17-4pH Stainless Steel Bar & Wire Rods |

|

|

|

17-4 Precipitation Hardening also known as Type 630 is a chromium-copper precipitation hardening stainless steel used for applications requiring high strength and a moderate level of corrosion resistance. High strength is maintained to approximately 600 degrees F (316 degrees Celsius).

17-4 pH Stainless Steel Bar || Precipitation hardening Steel || Alloy 630 || Euronorm 1.4542 || UNS S17400 |

Technical Specification:

| Size Range |

3mm upto 100mm, 1/8” upto 4”. |

| Supply Condition |

Cold Drawn & Polished.

Cold Drawn, Centerless Ground & Polished.

Peeled, Centerless Ground & Polished.

Peeled (Rough Turned.

Buffed (Mirror Finish).

Chamfered(30/45/60 Degree).

Solution Annealed, Grit 240-320 Polish. |

| Grades (AISI) |

17-4pH commonly referred as Alloy 630,Euronorm 1.4542 ,UNS S17400,JIS 630 etc

Other Grades:15-5pH, pH13-8 Mo(precipitatin hardening steel) |

| Standards |

- ASTM A693 grade 630 (AMS 5604B) UNS S17400

- EURONORM 1.4542 X5CrNiCuNb 16-4

- AFNOR Z5 CNU 17-4PH

- DIN 1.4542

|

| Size Tolerance |

h8, h9 (DIN 671), h10, h11,ASTM A484, DIN 1013. |

| Length |

UPTO 6 Mtrs. |

| Testing |

Ultrasonic Flaw Detection tests, Lab Chemical Analysis, Physical Anaylsis, Micro Analysis |

| Packing |

In 250 to 1000 Kgs. export worthy bundles, wrapped with HDPE cloth and strapped with metal strips at 3-4 places. Identification labels are tagged according to standard specification with color code. Wooden boxes are provided on demand. Each bar can be packed in protective folio on demand. |

| Corrosion Nature of 17-4 pH |

Alloy 17-4 PH withstands corrosive attacks better than any of the standard hardenable stainless steels and is comparable to Alloy 304 in most media.

If there are potential risks of stress corrosion cracking, the higher aging temperatures then must be selected over 1022°F (550°C), preferably 1094°F (590°C). 1022°F (550°C) is the optimum tempering temperature in chloride media.

1094°F (590°C) is the optimum tempering temperature in H2S media.

The alloy is subject to crevice or pitting attack if exposed to stagnant seawater for any length of time.

It is corrosion resistant in some chemical, petroleum, paper, dairy and food processing industries (equivalent to 304L grade).

If you would like to know more about 17-4PH stainless steel then click 17-4PH Technical Data. |

| Typical physical properties for stainless steels alloy 17-4PH |

| Property |

Value |

| Density |

7.75 kg/m3 |

| Modulus of Elasticity |

196 GPa |

| Electrical Resistivity |

0.080x10-6 Ω.m |

| Thermal Conductivity |

18.4 W/m.K |

| Thermal Expansion |

10.8x10-6 /K |

| |

|

|

| Mechanical properties |

| Material Type |

Condition |

Ultimate Tensile Strength (PSI) |

0.2% Yield Strength (PSI) |

Elongation (% In 2in.) |

Reduction Of Area (%) |

Hardness Brinell |

Hardness Rockwell |

| 17-4 PH |

H900 |

190,000 |

170,000 |

10 |

40 |

388 |

C40 |

| 17-4 PH |

H1025 |

155,000 |

145,000 |

12 |

45 |

331 |

C35 |

| 17-4 PH |

H1075 |

145,000 |

125,000 |

13 |

45 |

311 |

C32 |

| 17-4 PH |

H1150 |

135,000 |

105,000 |

16 |

50 |

277 |

C28 |

| 17-4 PH |

H1150-M |

115,000 |

75,000 |

18 |

55 |

255 |

C24 |

| 17-4 PH |

H1150-D |

125,000 |

105,000 |

16 |

50 |

255 min - 311 max |

C24 - 33 |

|

Application of 17-4 pH Steel |

- Offshore (foils, helicopter deck platforms, etc.)

- Food industry

- Pulp and paper industry

- Aerospace (turbine blades, etc.)

- Mechanical components

- Nuclear waste casks

Also in Petrochemical Plants, Dairy Equipments, Oil Pipeline Ships, Structural Design, High Tensile Springs & Cables, Boilers, Pressure Vessel, Liquid Storage Terminals, Liquid Cargo Ships, Pump Shafts, Valves. |

|

|

|

|

|

|

|

|

|

|

| |

|

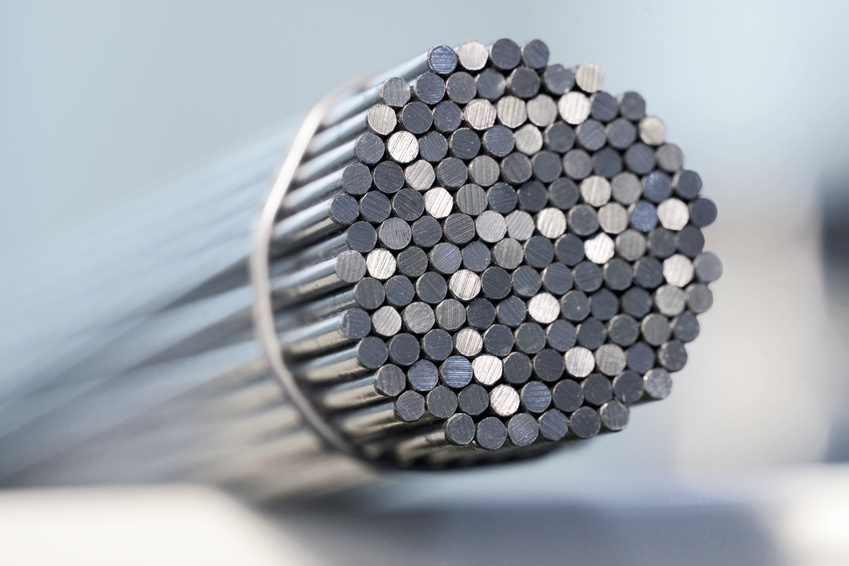

17-4 pH Stainless Steel Wire Rods |

|

|

|

We are instrumental in providing our clients with Stainless Steel Wire Rods that is applied for varied purposes like free cutting, welding and cold heading. These rods are available in sizes like 5.5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22 and 23 MM diameter. Moreover, the coil size of these rods are offered in the range of 850 MM to 1200 MM diameter. The detailed technical specifications of these rods are tabulated below:

| Size range |

2,3,4,5.5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22 and 23 MM Dia |

| Supply Condition |

Hot Rolled, Hor Rolled Pickled, Hot Rolled Annealed & pickled (HRAP) |

| Size Tolerance |

5.5 TO 10 MM: + / - 0.20 MM

1.1 TO 16 MM: +/ - 0.25 MM

17 to 23 MM : +/ - 0.30 MM |

| Size of coil |

850 MM to 1200 MM Dia. |

| Weight of coil |

900 to 1000 Kgs. |

| Grades (AISI) |

17-4pH commonly referred as Alloy 630,Euronorm 1.4542 ,UNS S17400,JIS 630 etc

Other Grades:15-5pH,pH 13-8 Mo( precipitation hardening steel) |

| Testing |

Ultrasonic Flaw Detection tests, Lab Chemical Analysis, Physical Anaylsis, Micro Analysis |

| Packing |

The coils are properly packed with HDPE cloth and strapped with signode straps. |

| Usage |

- Offshore (foils, helicopter deck platforms, etc.)

- Food industry

- Pulp and paper industry

- Aerospace (turbine blades, etc.)

- Mechanical components

- Nuclear waste casks

Also in Petrochemical Plants, Dairy Equipments, Oil Pipeline Ships, Structural Design, High Tensile Springs & Cables, Boilers, Pressure Vessel, Liquid Storage Terminals, Liquid Cargo Ships, Pump Shafts, Valves. |

|

|

|

| |

|

|

|